Your journey begins with steel. Through traditional or digital mold-making techniques, a rigorous process ensures that your product becomes mass-producible while retaining its unique look and character.

Take a look inside and download our brochure to find out more about our capabilities and services

Traditional Mold Making

-

Casting

Moving from positive to negative marks the start of mold creation. It's more than splitting a figure. Our engineers dissect unique forms, crafting a metal-based system around them, forming the mold's foundation.

-

Adjustment

After casting, mold makers merge precision-machined metal with cast parts. Their goal: an airtight seal in the mold's seams. Fully assembled, it's a complex puzzle. Each tweak affects structural integrity. This stage demands precision.

-

Final Touches

When finished, assembled, and fine-tuned, the molds undergo a meticulous final adjustment process, necessitating the calibration of both the mold and machine settings before being sent to our production facility.

Digital Mold Making

-

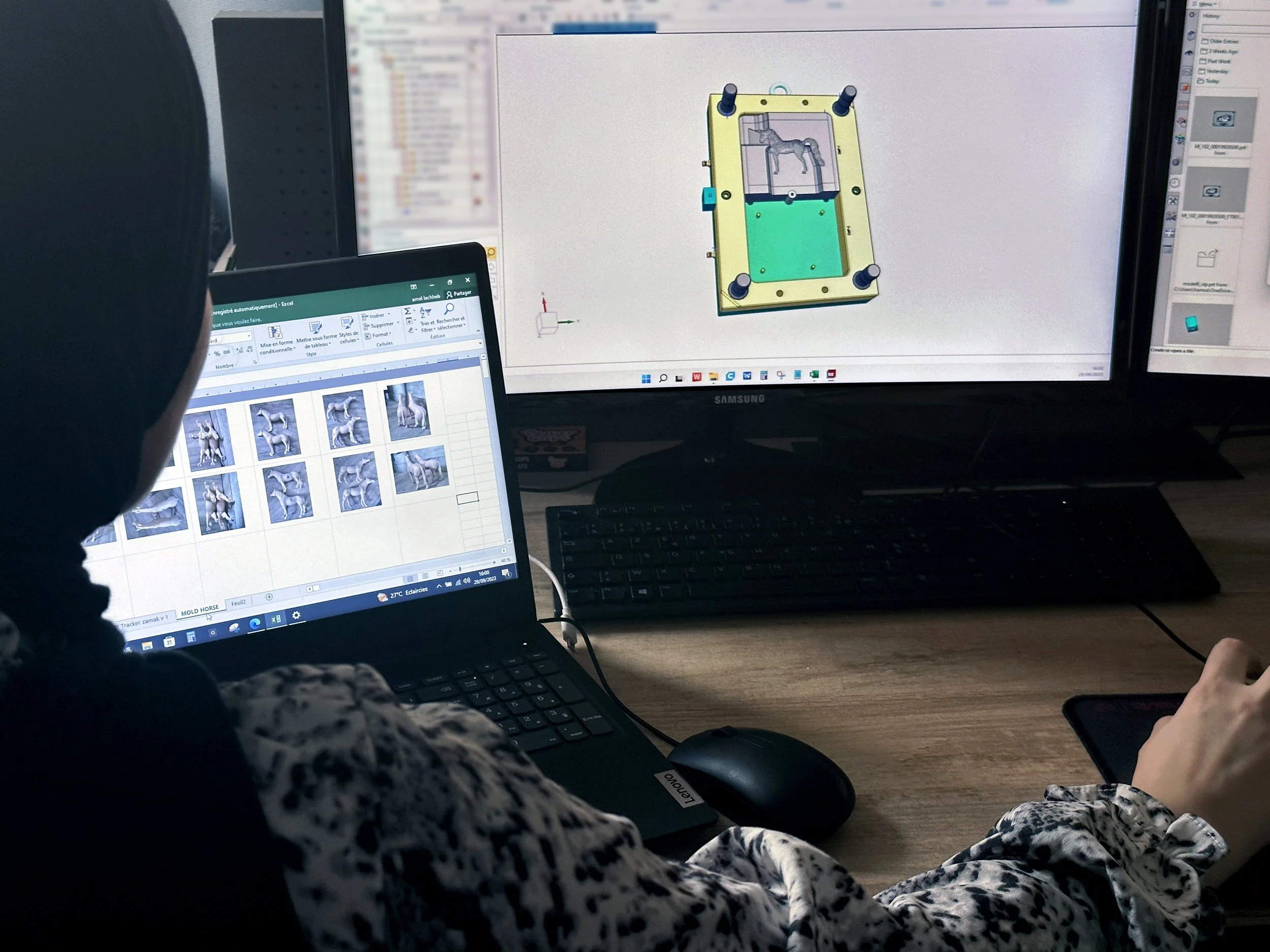

DIgital Conception

Enhancing the technicians' expertise by combining their visual and tactile observations with computer software designed for mold simulation enables a comprehensive exploration of mold intricacies. This approach empowers the experts to meticulously craft a complete digital mold.

-

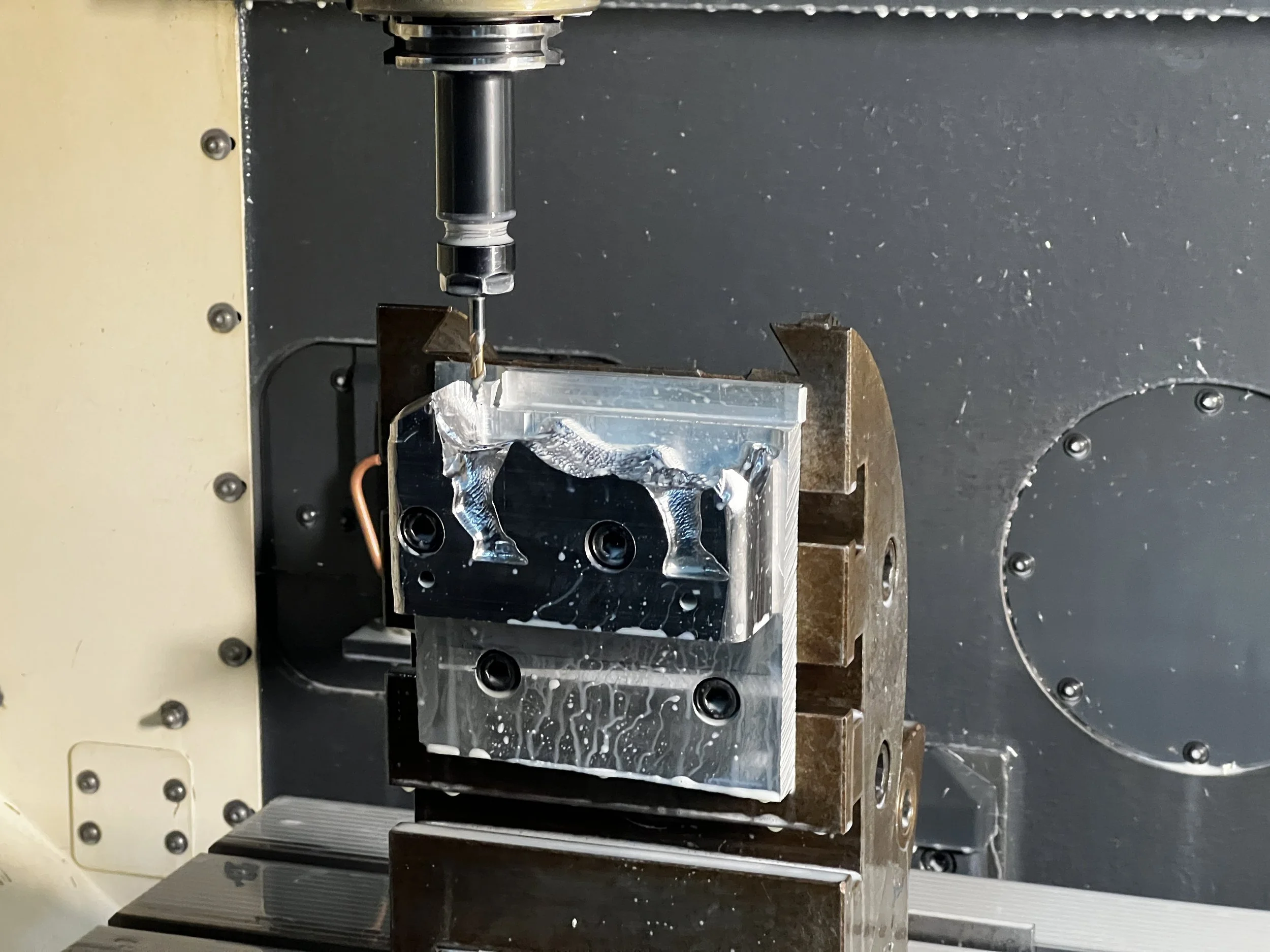

Machining

Utilizing precision machines, our engineers can seamlessly translate their digital concepts into a tangible physical form. Unconstrained by the spatial limitations of the CNC engraver, they possess the capability to craft meticulously fitted components, ensuring a seamless integration into the final product.

-

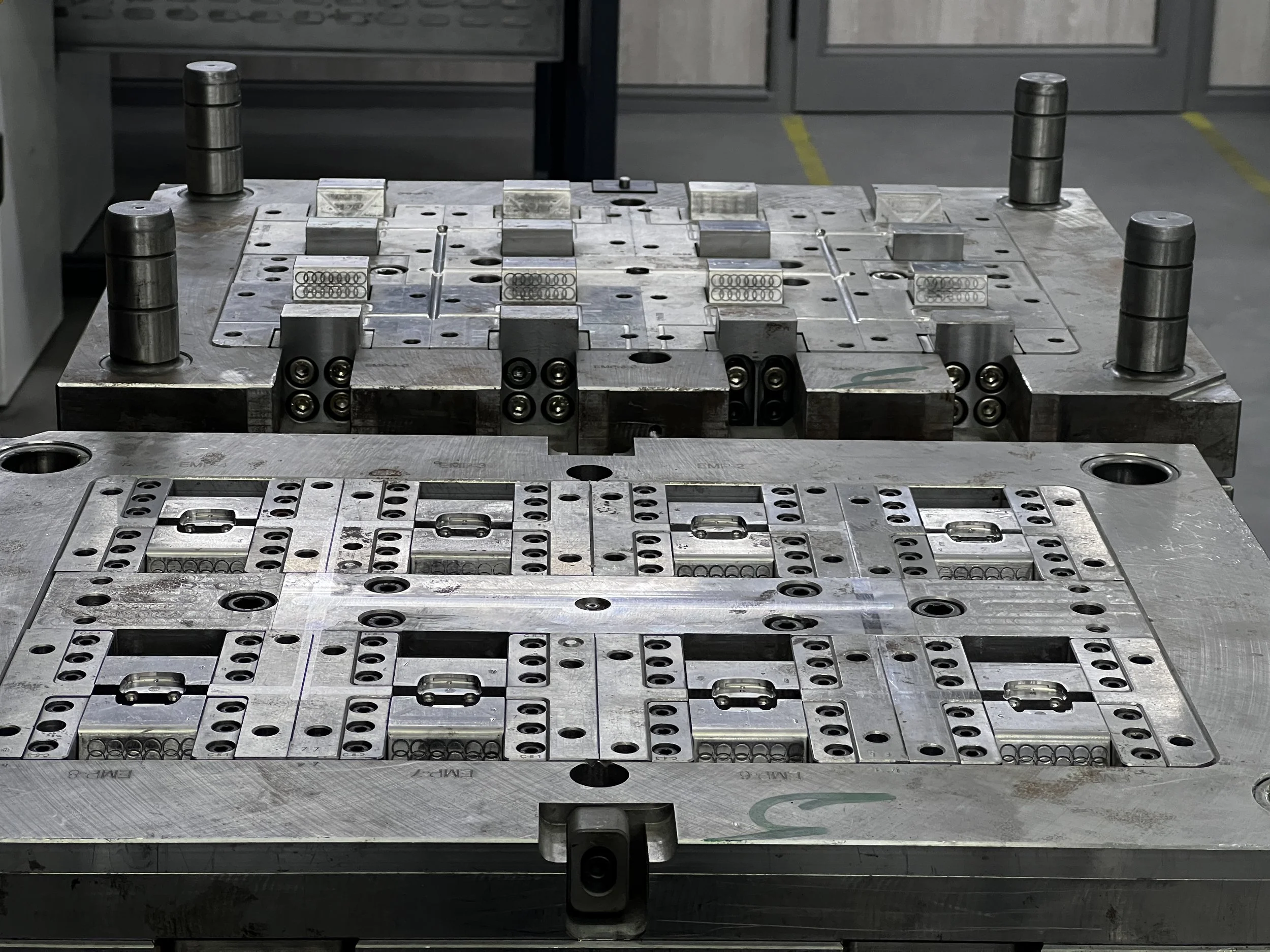

Repeatability

After the validation and confirmation of the design and fitting, this process unlocks the potential for virtually limitless reproducibility of the mold. This not only facilitates rapid capacity expansion but also streamlines the repair and maintenance of existing molds, ensuring sustained operational efficiency.

We are Ready to Create

Together, we can cast and mill your product into reality. You bring the challenge, and we provide the solution.